This six-week immersion training includes training in everything from Microsoft Office and professional skills to Revit, Navisworks and AutoCAD.

Week 1: Technical Skills

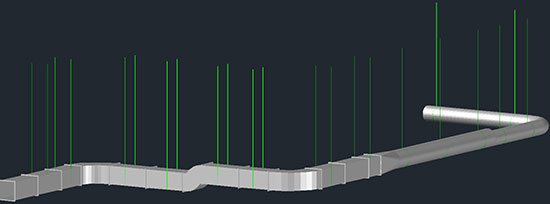

The first week of BIMmersion covers the understanding of how to coordinate, fabrication process, proper installation and labor savings in regards to Mechanical Ductwork, Mechanical Piping, Mechanical Plumbing and Electrical. Coordination of Pneumatic Tubing will also be discussed. The students will gain knowledge in regards to proper duct design and the use of a Ductulator. Reading Plans and Specifications will be covered as well as Reading Submittals and Shop Drawings. The students will learn different techniques to cleaning up drawings and preparing them for drawing creation. Creating spooled/prefabrication drawings will be discussed and demonstrated. The students will learn how to create hanger points, floor openings, etc. through point layout software and have the ability to export them into a device that can be used for the location of these points on a particular jobsite.

Week 2: BIM Theory, Professional Skills and Microsoft Office

During the second week, students will learn what BIM is from the Sheet Metal Workers perspective and what value it has to the construction industry. Students will also learn about the theories or paradigms that they'll work under and how to navigate between two opposing paradigms.

Professional skills covers the importance of communication and how to effectively communicate both orally and in written forms using different platforms.

In the Microsoft Office portion, the student will learn how to use Microsoft's Word, Excel, and Outlook programs as they would be used at a contractor.

Required reading prior to taking BIM Theory: Orbiting the Giant Hairball by Gordon MacKenzie. (The ITI does not provide this book. Either purchase from a bookstore or obtain a copy from your local public library.)

Week 3: Fabrication and Drafting Software

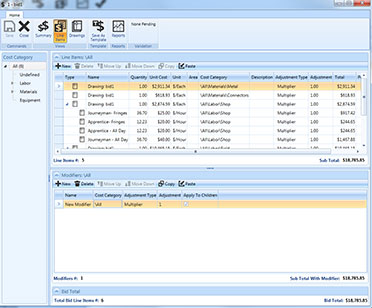

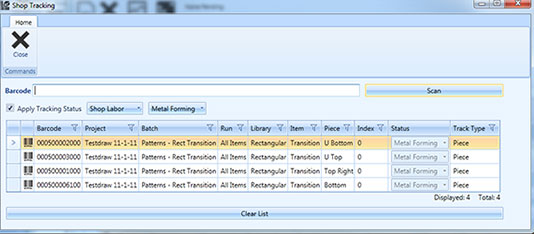

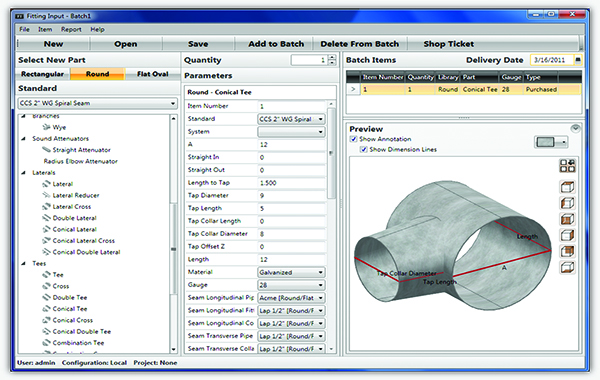

During the third week, the use of the ITI's Benchmark Software is covered. The student will learn how to create 3D models in side AutoCAD with the aid of Benchmark Draft Software. The AutoCAD drawing is downloaded and used for fabrication of the sheet metal parts. The students will learn how to do the following through the Benchmark Fabrication Software. Setting up your company's plasma table, manage how patterns are nested onto sheet sizes, manage and print labels for fabrication, process downloads from the detailer and update batch statuses.

Week 4: Revit and Navisworks

During the fourth week, students will learn how to use Autodesk Revit and NavisWorks software.

Revit training will go over: learning the basics of Revit, creating views of the model, setting up levels and grids, creating walls, floors, ceilings, roofs, stairs, railings, ramps, etc., adding components to the model, creating and printing sheets, adding annotations and a detailing a sheet, creating HVAC systems, creating hydronic systems, creating plumbing systems and creating lighting and power plans.

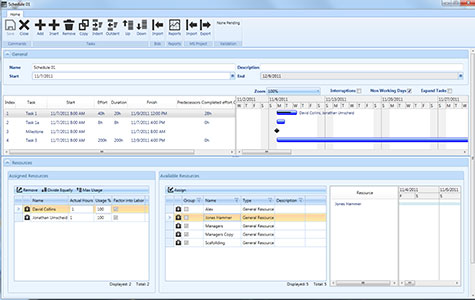

NavisWorks training will go over: learning the main features and functionality of the NavisWorks software, open and append 3D files of different formats and save in the NavisWorks format, perform visual project model reviews using built-in review and reporting tools, perform interference detection tests between 3D files of different disciplines to check integrity of the design, obtain takeoff data from source models to create material estimates, measure areas, and count components.

Week 5: Cobie, SMACNA and Mechanical, Electrical and Plumbing Codes

During the fifth week, students will learn about Construction Operations Building Information Exchange (Cobie), Omni Class, and Industry Foundation Classes (IFC) and their importance to BIM.

The SMACNA duct construction standards for ductwork and hangers will be covered and students will be able to properly create these standards for use at a contractor upon completion.

In the code section, mechanical codes for H.V.A.C. duct and piping, electrical, and plumbing will be taught and students will have an understanding of their importance in the design of MEP systems for a construction project.

Week 6: Advanced AutoCAD, Total Station, Autodesk and Abode workshops

During the final week, attendees will builds on the basic concepts of the AutoCAD Fundamentals. This course is designed for the user who needs to upgrade their skills. The course is designed to teach the advanced tools and techniques to become more productive while creating, annotating and printing drawings while using AutoCAD. Students will learn to use task commands more efficiently and will work with advanced blocks, XREFS, layouts and plotting. Students' proficiency and productivity will be enhanced by simple, yet powerful customization tools.

This section will cover the use of a Total Station. The students will learn how to use a total station to layout hangers, hole openings, wall openings and any other layout that is required. They will load data that has been created by a detailer via a 3D drawing program or point software, to locate these hanger and hole points.

Students will also be taught how to use Autodesk Constructware and Adobe software.

Constructware training will go over: learning the basics of Constructware software, Accessing centralized information easily, Managing Files, Improving risk management, Controlling Costs and Data Exchange.

Adobe training will go over: learning the basics of Adobe software, such as creating and customizing PDFs, searching, editing text and graphics, and extracting PDF content to use in other programs.